Diffusion Bonding Crystals

Description:

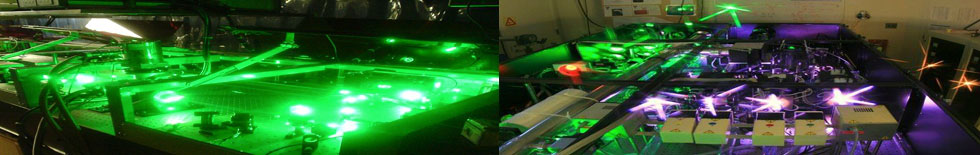

Diffusion Bonded Crystals are crystals consisting of two, three or more parts with different doping levels or different dopant, usually one laser crystal and one or two undoped crystals combined by optical contact and further bonded under high temperature. This innovative scheme reduces thermal lens effect of laser crystals, provides integral components to make compact lasers.

|  |  |

Standard Diffusion Bonded Crystals

Cr4+:YAG +Nd:YAG

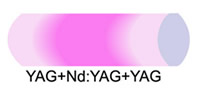

YAG + Nd:YAG + YAG

Yb:YAG + YAG

Yb:YAG + Cr4+:YAG

YVO4 + Nd:YVO4 + YVO4

Diffusion bonding means that the two parts that are bonded together diffuse into one another and they become as one single crystal. The technology of diffusion bonding includes the following steps:

Perfect optical contact between the crystals to be bonded;

Heating up of the two parts very slowly (within 24 hours or even more), to a very high temperature, probably 2/3 of the melt temperature or more, and exerting pressure to press the two parts together;

Keeping the bonded crystals for certain period of time at this high temperature, so that diffusion takes place;

Slowly cooling the crystals (24 hours or even more) down to room temperature.

Applications:

These Diffusion Bonded composite crystals are used to effectively decrease heat effect of Solid-State High-Power Laser:

High damage threshold;

Improve beam quality;

Decrease thermal effect;

Improve efficiency;

Compact size.

Specifications:

| Nd:YVO4 Doping | atm 0.2-3% |

| Nd:YAG Doping | 0.5-1.1% |

| Wavefront Distortion | < λ/8 @ 633 nm |

| Orientation | ±0.5deg. |

| Dimensional Tolerance | ±0.1mm |

| Surface quality | 10/5 Scratch/Dig per MIL-O-13830B |

| Flatness | λ/10 @ 633 nm |

| Clear Aperture | > Central 90% |

| Parallelism | < 10 arc sec |

| Intrinsic Loss | < 0.1% cm-1 |

| Coating | AR or HR coating |

Yb:YAG+Nd:YAG+Cr:YAG |  |

Nd:YAG+Yb:YAG+YAG |  |

Bonding rod (NdYAG) |  |

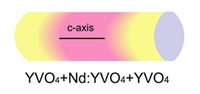

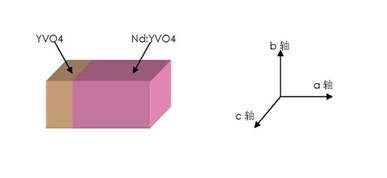

YVO4+NdYVO4 |  |

BBO+BBO(walk-off angle compensation) |  |